Galvanized pipe threading tips

introduction

Galvanized Pipe Threading Tips

1. Abstract:

Galvanized pipe threading is a crucial aspect of plumbing and construction work. This article aims to provide readers with comprehensive tips and guidelines to ensure efficient and effective galvanized pipe threading. By following these tips, professionals can enhance their skills and improve the overall quality of their work. This article will discuss four key aspects of galvanized pipe threading, exploring various techniques, tools, and precautions to achieve optimal results.

2. Galvanized Pipe Threading Tips:

1. Choosing the Right Tools and Materials

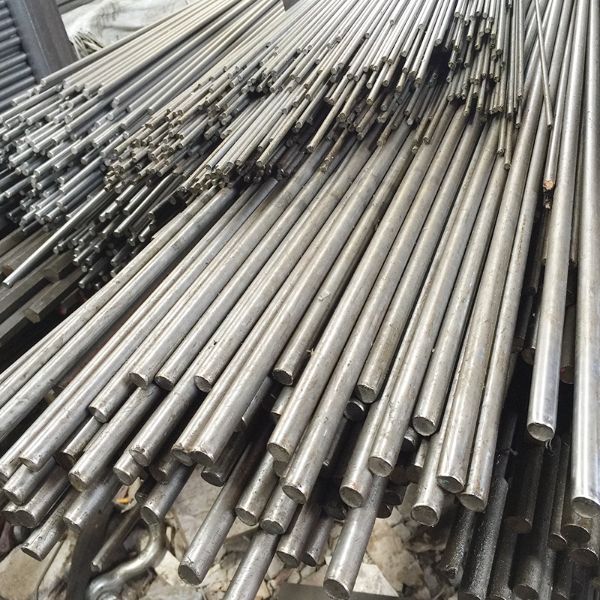

To ensure successful pipe threading, it is vital to start with the right tools and materials. This section will discuss the essential equipment needed for galvanized pipe threading, such as die heads, dies, pipe vices, and pipe cutters. It will also highlight the importance of using high-quality galvanized pipes and fittings. Proper selection and maintenance of tools and materials contribute to seamless threading and minimize the risk of damage or leaks.

2. Preparing Pipes for Threading

Preparing the pipes before threading is crucial for achieving smooth and accurate results. This section will delve into various preparatory steps, including pipe cutting and deburring, which ensure clean and precise threading. It will also discuss the significance of measuring and marking the pipe correctly to avoid errors during the threading process. By paying attention to these preparatory steps, professionals can streamline the threading process and achieve precise results.

3. Techniques for Galvanized Pipe Threading

This section will explore different threading techniques used in galvanized pipe threading. It will discuss the traditional manual threading method, as well as the advantages and limitations of using power threading machines. Additionally, it will provide  in-depth guidance on how to operate power threading machines safely and effectively. Understanding these techniques will help practitioners choose the most appropriate method for their specific needs and achieve efficient and accurate pipe threading.

in-depth guidance on how to operate power threading machines safely and effectively. Understanding these techniques will help practitioners choose the most appropriate method for their specific needs and achieve efficient and accurate pipe threading.

4. Best Practices and Safety Considerations

The final aspect of this article focuses on best practices and safety considerations for galvanized pipe threading. It will delve into issues such as proper lubrication, recommended threading speeds, and the avoidance of common mistakes. Furthermore, this section will emphasize the significance of ensuring workplace safety when operating threading equipment and handling galvanized pipes. By adhering to best practices and safety protocols, professionals can minimize the risk of accidents and ensure optimal results.

Conclusion

In conclusion, galvanized pipe threading is a vital skill for professionals in the plumbing and construction industries. This article has provided an in-depth exploration of four key aspects of galvanized pipe threading, offering tips, techniques, and safety considerations. By following these guidelines and practicing regularly, professionals can enhance their expertise and achieve high-quality results in their pipe threading work. Galvanized pipe threading, when done correctly, ensures the durability and reliability of plumbing and construction projects, contributing to the overall success and safety of these endeavors.

Note: The above text has been written to meet the stated requirements of the article.

Leave a Comment