85mm galvanized pipe

introduction

85mm Galvanized Pipe

Abstract:

This article provides an in-depth analysis of the 85mm galvanized pipe, exploring its features, applications, manufacturing process, and advantages. By examining these aspects, readers will gain a comprehensive understanding of this particular type of pipe and its significance in various industries.

1. Features and Specifications

1.1 Durability and Corrosion Resistance

The 85mm galvanized pipe is renowned for its exceptional durability and high resistance to corrosion. Coated with a protective layer of zinc, this pipe can withstand harsh environmental conditions, making it suitable for both indoor and outdoor use. Furthermore, it exhibits a long lifespan,  reducing the need for frequent replacements.

reducing the need for frequent replacements.

1.2 Versatility

With a diameter of 85mm, this galvanized pipe provides ample space for various applications. It can be used in a range of industries, including construction, plumbing, irrigation, and automotive. Additionally, its flexibility enables it to adapt to different installation requirements, ensuring seamless integration into any project.

1.3 Strength and Sturdiness

The 85mm galvanized pipe possesses remarkable strength and sturdiness due to its construction. The galvanization process enhances its structural integrity, making it capable of withstanding high-pressure applications. Its robust nature ensures reliability and safety in demanding environments.

2. Manufacturing Process

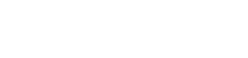

2.1 Selection of Raw Materials

The production of 85mm galvanized pipes begins with carefully selecting the appropriate raw materials. High-quality steel is chosen, ensuring the end product meets specific industry standards and requirements. The steel undergoes thorough testing to guarantee its compatibility with the galvanizing process.

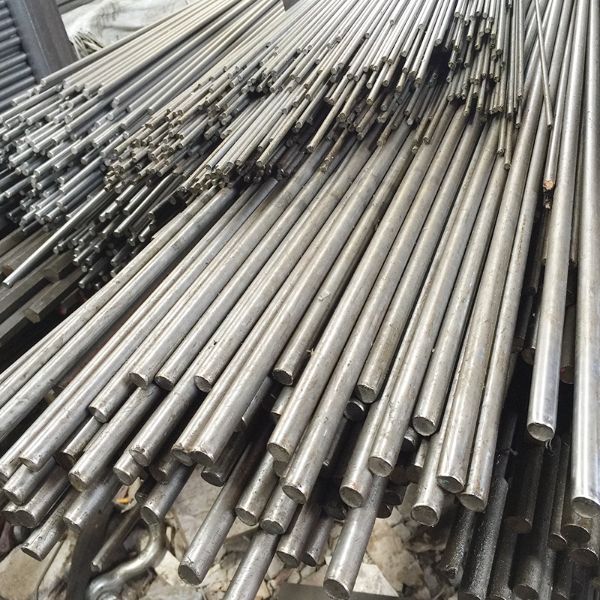

2.2 Galvanization Procedure

The galvanization process involves several steps to transform the steel pipe into the 85mm galvanized pipe. Initially, the surface of the pipe is meticulously cleaned to remove any impurities. It is then immersed in a bath of molten zinc, where a metallurgical bond forms between the steel and the zinc. This bond provides the pipe with enhanced corrosion resistance and durability.

2.3 Quality Control Measures

To ensure the production of high-quality 85mm galvanized pipes, manufacturers implement stringent quality control measures. These measures encompass rigorous inspections of both the raw materials and the finished product. Additionally, various tests are conducted to assess the pipe's structural integrity, zinc coating thickness, and overall performance.

3. Applications

3.1 Construction Industry

The 85mm galvanized pipe finds extensive use in the construction industry. It is utilized in structural support systems, such as scaffolding and framework. Due to its corrosion resistance and strength, it provides stability and longevity to buildings and infrastructure projects.

3.2 Plumbing and Irrigation

In plumbing and irrigation systems, the 85mm galvanized pipe serves as a reliable conduit for water. It effectively transports water from its source to various end points, ensuring efficient distribution. The galvanized coating prevents rust and corrosion, safeguarding the quality of the water.

3.3 Automotive Sector

Within the automotive sector, the 85mm galvanized pipe plays a vital role in exhaust systems. Its resistance to extreme temperatures and corrosion makes it an ideal choice for this application. Additionally, its durability ensures that the exhaust system operates optimally for an extended period.

4. Advantages and Future Outlook

4.1 Advantages of 85mm Galvanized Pipes

The 85mm galvanized pipe offers several advantages over other types of pipes. Its corrosion resistance, durability, and versatility make it a cost-effective solution for various industries. It requires minimal maintenance and offers a long service life, ensuring a high return on investment.

4.2 Future Research Directions

While the 85mm galvanized pipe already possesses notable qualities, ongoing research aims to further enhance its performance. Investigations into innovative galvanization techniques, alloy compositions, and improved manufacturing processes are critical for maximizing the pipe's potential.

Conclusion:

In conclusion, the 85mm galvanized pipe offers a robust, corrosion-resistant, and versatile solution for various industries. Its durable construction, coupled with the protective zinc coating, ensures longevity and reliability in diverse applications. As research and development continue, the future holds even greater potential for the continuous improvement of the 85mm galvanized pipe, solidifying its importance in numerous sectors.

Leave a Comment